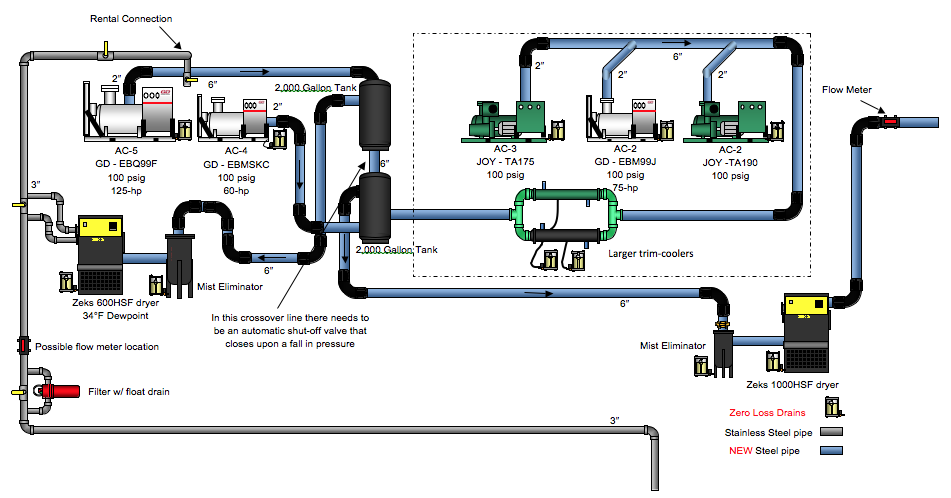

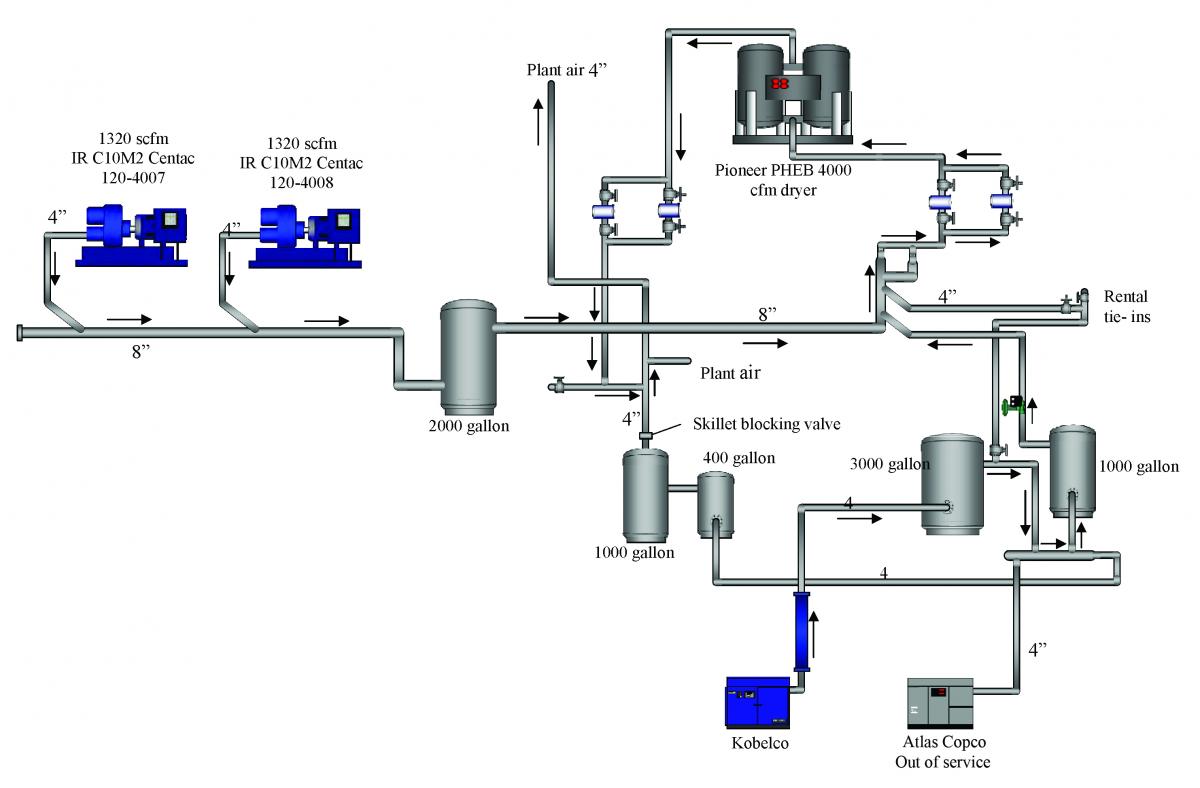

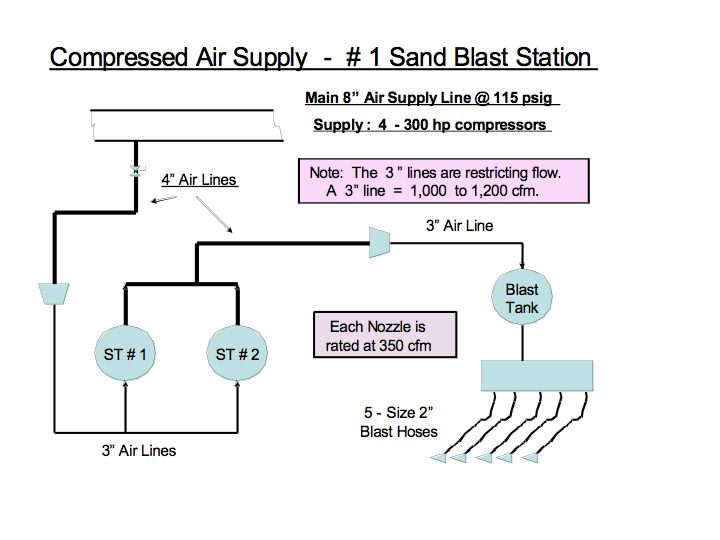

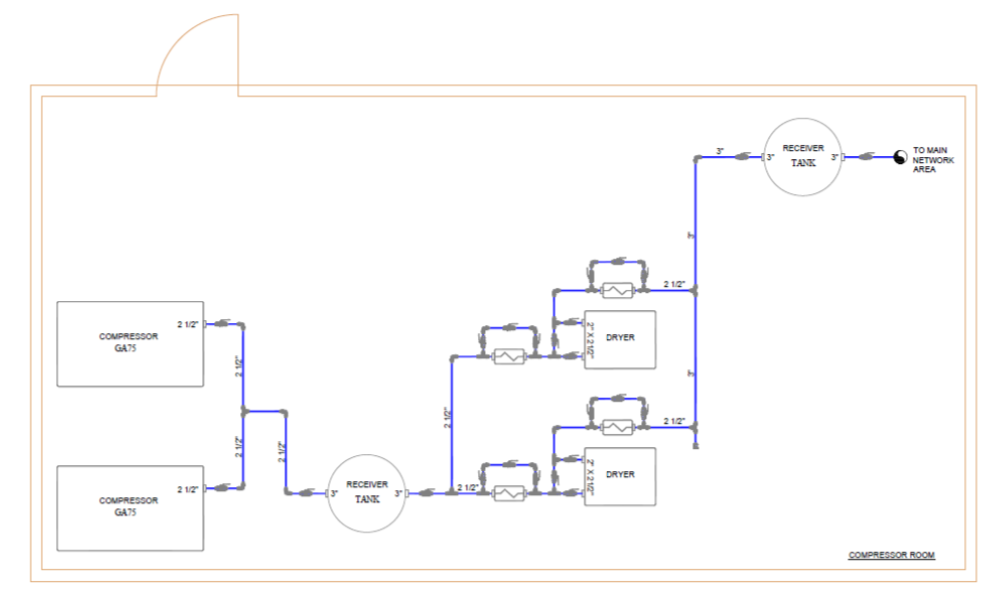

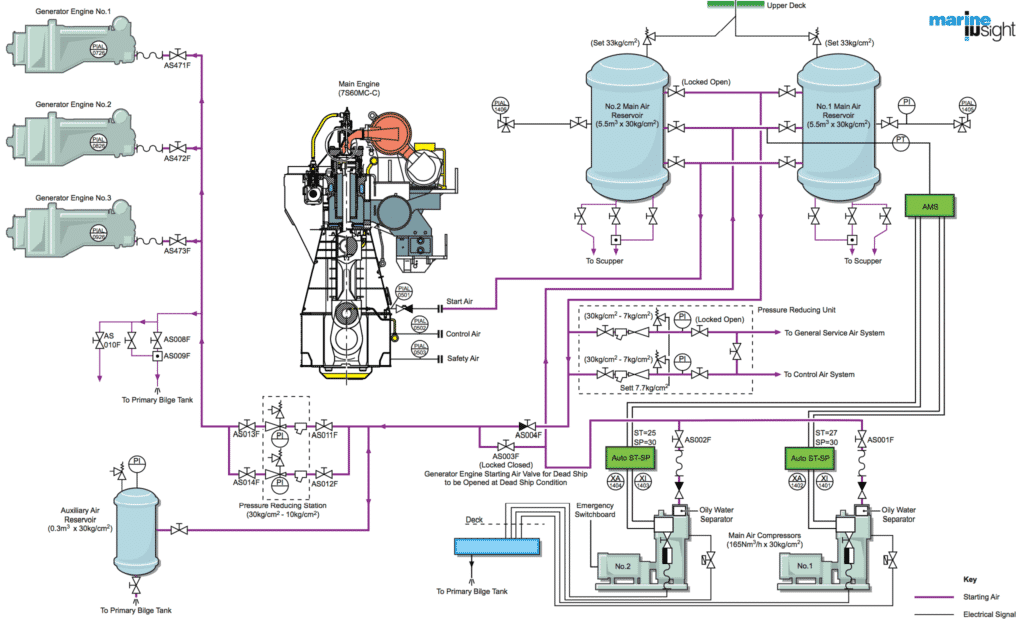

43 compressed air system piping diagram

Compressed Air System Basics - YouTube Understanding Compressed Air Systems and the importance of keeping air dry. Learn more about Tsunami Compressed Air Solutions: ... Air Piping Layout - Sharpe Manufacturing The quality of our compressed air is also effected by how our air delivery lines are laid out in our shops. The following two diagrams will show you a very good layout for shop air piping. I have also provided links so you may download these diagrams to your hard drive in Adobe PDF format where you can then print for future reference.

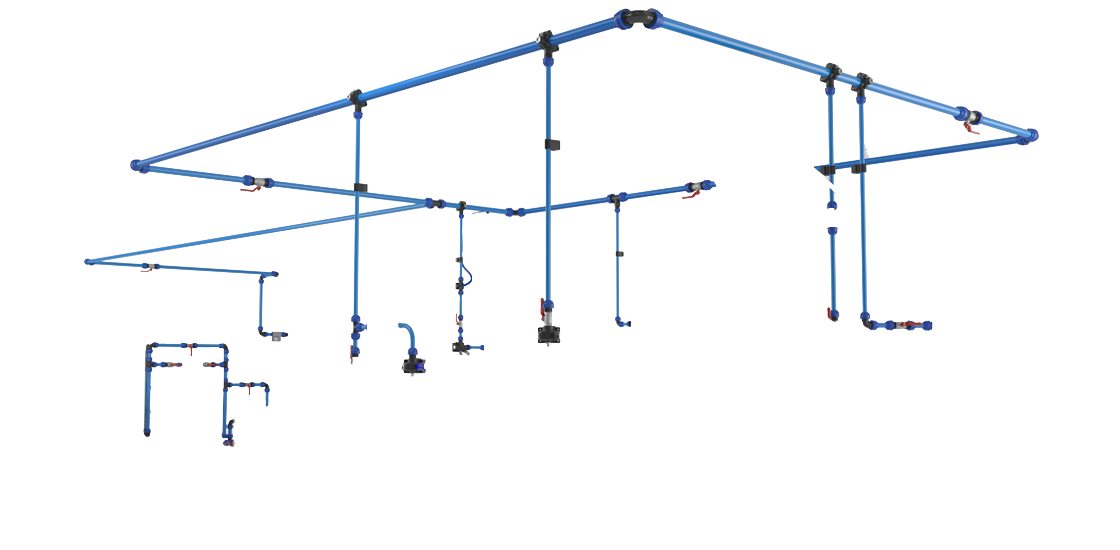

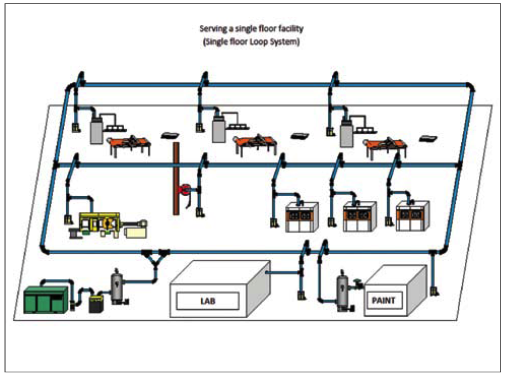

Using Straight Line and Looped Designs for Compressed Air ... One solution that is recommended is using a looped system for your compressed air piping layout. Unlike a design with sharp corners, the looped structure allows gas to flow to all parts of the system unobstructed. Because the fluid flows with little resistance, it can increase the technical rating of a looped layout compared to straight-line pipes.

Compressed air system piping diagram

PDF Compressed Air Piping Recommendations for Compressor ... Compressed air piping materials can be divided into two basic types: metal and non-metal. Non-metal pipe is commonly called thermoplastic pipe. In our experience, thermoplastic should be used only in some air compressor inlet piping situations, which are not Compressed air piping systems are complex and require careful planning. Air Compressor Piping Diagrams And Tips - iPower Toolz Various aspects need to be taken under consideration while creating an air compressor piping diagram. Like for instance moisture, or any snag, layout, etc. In my perspective piping is the deal-breaker, as it can either make your business or break it. A fault in the pipeline means loss of power, which in other words means more unnecessary expenses. Compressed Air Piping | Air Treatment|Gardner Denver Aluminum piping will keep your compressed air extremely clean, as it is non-corrosive. Unlike plastic pipe, aluminum can stand up over time without becoming brittle or weak. Aluminum piping is push to connect in many circumstances, making installation easy and cost effective. During the installation process, it is also best to avoid 90 degree ...

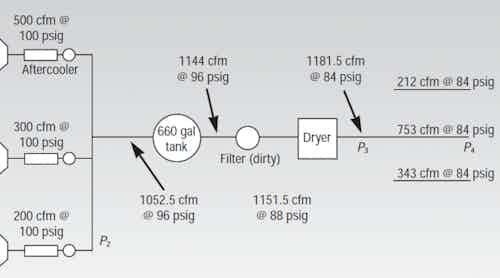

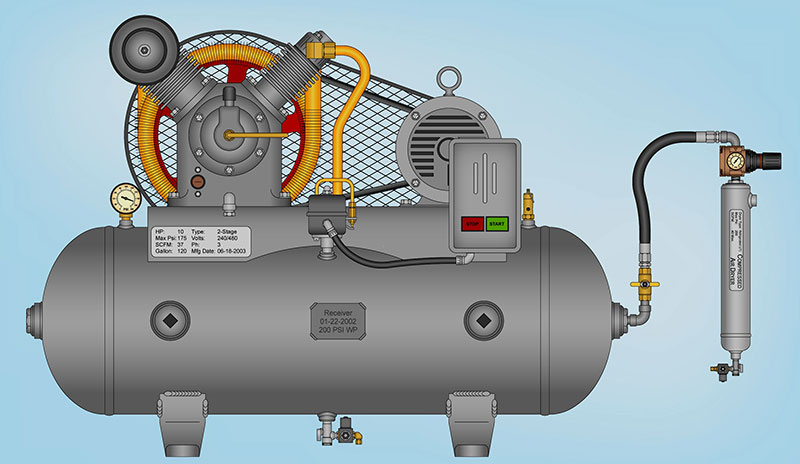

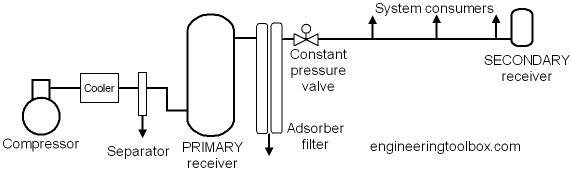

Compressed air system piping diagram. Designing Your Compressed Air System - KAESER our compressed air system is a critical plant utility.To function properly and cost effectively, it must be carefully designed to fill the special needs of your applications. Six basic elements—demand, compressed air quality, supply, storage, distribution, and control/management—must be evaluated and factored into final layout Industrial Compressed Air System Design & Piping Layout ... The key to achieving the supply of high quality compressed air is the creation and implementation of an optimized compressed air system plan. This article will consider the various aspects of the design and piping layout required to properly produce and transport compressed air free of impurities. Air Compressor Piping Diagrams and Tips - Best of Machinery When there are lots of sharp angles in an air compressor piping diagram, the following happens: The speed of air slows down The flow of air is interrupted The pressure decreases Just like when you're driving, you must decrease your speed if you need to make a sharp turn. The same applies to air in an air compressor pipe system. Parts Of An Air Compressor Diagram Guide - Air Compressor ... Air compressors consist of many components to ensure that your system provides high-quality compressed air, and so, it can often be difficult to understand the role of each component. This article will provide you with a few annotated diagrams of air compressor systems, with descriptions about each part to follow.

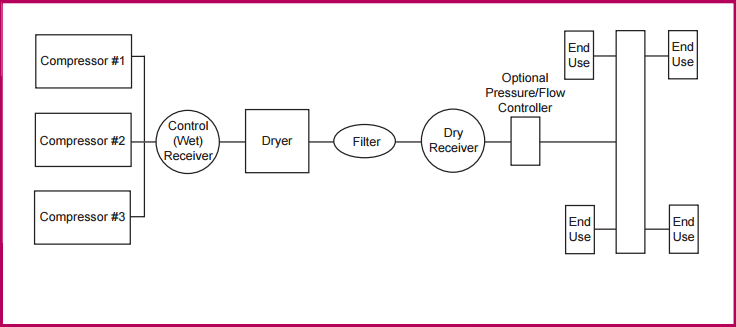

Air compressor piping diagrams and tips | Learn from the ... Air piping diagram angle When working on your air compressor hose diagram, you should always avoid sharp angles. This has pretty detrimental effects on piping air to the air tool. Because these sudden sharp angles slow down the flow of air, and as a result, the pressure also drops. Let me explain it with an example. Compressed Air Basics - Piping - Air Compressor Works, Inc. To minimize pressure drop: Make sure you have the proper pipe size for the CFM, pressure, and length of your pipe system. The longer you go, the bigger the pipe will need to be. We have charts and excel spreadsheets that calculate pressure drop in piping. You can also look on-line for numerous pressure drop calculators. Compressed Air Piping - Emax Compressor Rapid Air 3/4″ Maxline Compressed Air Piping System Master Kit. Silent Air Technology. QUICK LINKS. Rotary Screw Air Compressors Piston Air Compressors Air Compressor Pumps Compressed Air Dryers Air Compressor Tools Air Compressor Parts & Accessories. RESOURCES. Find Service Warranty Plans Manuals Air Compressor Installation Guide - Tips & Setup Diagram Compressed Air System Configuration. Every company's needs are unique, but when installing a compressor system, we generally recommend that systems include a wet receiver between the compressor and air dryer and a dry receiver after the dryer. The compressor should have a moisture separator. The dryer should have a pre-filter and an after filter.

Installing Compressed Air Piping System from your Piping ... RapidAir Products is your one source for all your compressed air piping needs, from the flexible RapidAir and Maxline tubing, to the hard piped blue aluminum... Compressor Inlet Piping | Compressed Air Best Practices The working pressure of copper piping is 250 psi for Type "M" hard, Type "L" hard, and Type "K" soft, and 400 psi for Type "K" hard. Further, since 50/50 solder melts at 421 •F, it will be more resistant to high temperatures. Even if it does fail, it will do so in a predictable manner. The pipe ends will separate. PDF Compressed Air System Standard Piping Diagram Compressed Air System Standard Piping Diagram Author: Department of Veterans Affairs, Office of Acquisition Logistics and Construction, Office of Construction and Facilities Management, Office of Facilities Planning, Facilities Standards Service Subject: Standard Detail Created Date: 10/26/2017 1:02:30 PM Air System Piping - Quincy Compressor Pipes 20 (3/4″) - 25 (1″) - 40 (1 1/2″) - 50 (2″) - 63 (2 1/2″) - 80 (3″) - 100 (4″) - 158 (6″) MM AIRnet is Reliable, Safe, and Maintenance Free Sustainability Optimized inner body design minimizes flow resistance and pressure drop in the fittings Low friction factor and seamless connections minimize pressure drops in the pipe network

Compressed Air Pipe Sizing Chart | Infinity Pipe Systems Choose the flow rate of the air compressor in the red column. Choose the distance between the air compressor and the furthest dropper or outlet point in the blue column. Cross the lines of compressed air flow rate and the blue column of distance to identify the aluminium air pipe diameter. Pressure 7 bar - Total pressure drop 4%

PDF How to know what size piping your Compressed Air System needs the overall air system. Steps to figuring what size piping your compressed air system needs: 1. Determine your air compressor's maximum CFM. 2. Draw a piping schematic and show all pipe fittings, valves, etc. 3. Measure and write the corresponding lengths of pipe on your schematic, then total the length of all straight pipes needed and note ...

Compressed Air Piping Distribution Systems | Compressed ... Closing the loop at the far end of the bays allowed the compressors to again operate at 95-100 psig. A 20 psig lower pressure meant 10% savings: 40 KWh = $ 30,000/year. Piping cost was $ 15,000. 3. A healthcare garment plant in the Southwest added a new, large, automatic packaging machine at the rear its converting area.

Air Compressor Piping Diagrams and Tips - Tools Haunt An air compressor piping diagram is created by connecting an air compressor to any end-user tool through the use of a pipe. As simple as it may sound, creating your own piping diagram at home is rather a complicated process. Besides, you need the specific requirements of your project to come up with the correct piping.

Compressed air - 3D CAD Models & 2D Drawings History. Industrial use of piped compressed air for power transmission was developed in the mid 19th century; unlike steam, compressed air could be piped for long distances without losing pressure due to condensation.An early major application of compressed air was in the drilling of the Mont Cenis Tunnel in Switzerland in 1861, where a 600 kPa (87 psi) compressed air plant provided power to ...

PDF Compressed Air System Design 4 - CAGI There are typically two methods for determining the total demand of a compressed air system; calculating or measur- ing. Both methods will be discussed below. 2 Calculating Air Flow Requirements Understanding your constituents of demand is the first step to properly sizing your system.

Compressed Air System Schematic Diagram - SYAHME1410 Figure 2 From Optimization Of Compressed Air Storage S . Volvo Service Bulletin 5 56 51 . Mellcon Hoc 7kg Cm2 100psi An Ideal Compressed Air System . Machinery Resale Offers Used Construction Equipment Solutions . A C Piping Diagram Shop Air Piping Layout Diagrams . A Hybrid Energy Storage System Using Pump Compressed Air And

Air Compressor Piping Diagrams and Tips From Experts ... It's important to reduce the number of elbows/sharp angles in your piping diagram. They reduce the speed of airflow and therefore cause pressure drop. The most efficient pathway is a straight one. This avoids energy being wasted as air ricochets around the pipe after a sharp angle. Regulating Moisture Levels

Guide to Compressed Air Piping Systems | Quincy Compressor When that air is compressed, the water in it condenses from its vapor form into a liquid state. There is a simple way to reduce moisture in the piping system : change the compressor's supply inlet source. The water resulting from compression weighs more than compressed air, which causes it to sink.

SimplAir Compressed Air Piping | Ingersoll Rand PROVIDES SOLUTIONS FOR VIRTUALLY ANY NEED Simplair® piping is available in a wide range of outer diameter sizes from 3/4" to 8" (20 mm to 220 mm) to serve nearly any application. High-quality, all-metal, easy-to-install fittings make it easy for users to design and construct their own systems without the need for professional installers.

PDF Introduction INTRODUCTION TO BEST PRACTICES FOR COMPRESSED ... "Fundamentals of Compressed Air Systems" and "Advanced Management of Compressed Air Systems" 1. Know what equipment you have. Develop a basic block diagram of compressors, dryers, filters, receivers, and other system equipment, as shown in the following Figure 1 (see Section 2.G for more details). 2. Know what is happening in your system.

Compressed Air Piping | Air Treatment|Gardner Denver Aluminum piping will keep your compressed air extremely clean, as it is non-corrosive. Unlike plastic pipe, aluminum can stand up over time without becoming brittle or weak. Aluminum piping is push to connect in many circumstances, making installation easy and cost effective. During the installation process, it is also best to avoid 90 degree ...

Air Compressor Piping Diagrams And Tips - iPower Toolz Various aspects need to be taken under consideration while creating an air compressor piping diagram. Like for instance moisture, or any snag, layout, etc. In my perspective piping is the deal-breaker, as it can either make your business or break it. A fault in the pipeline means loss of power, which in other words means more unnecessary expenses.

PDF Compressed Air Piping Recommendations for Compressor ... Compressed air piping materials can be divided into two basic types: metal and non-metal. Non-metal pipe is commonly called thermoplastic pipe. In our experience, thermoplastic should be used only in some air compressor inlet piping situations, which are not Compressed air piping systems are complex and require careful planning.

Comments

Post a Comment