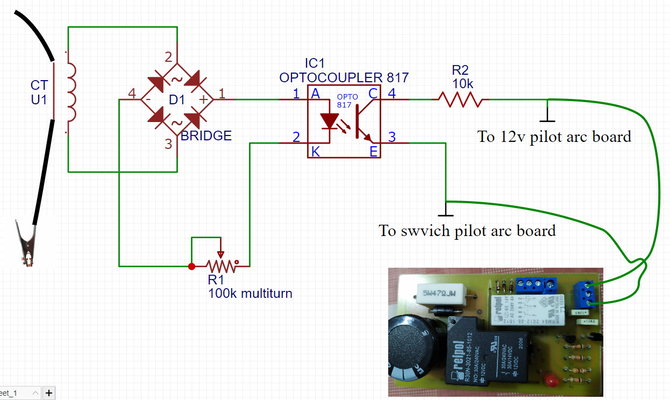

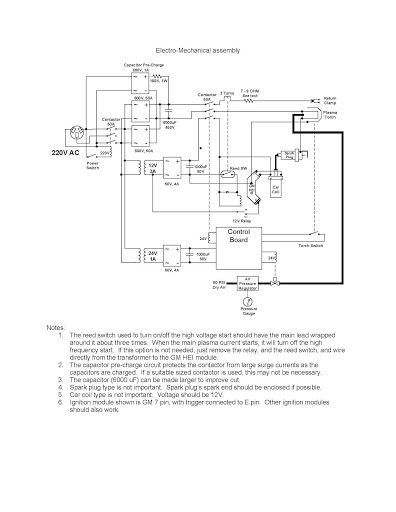

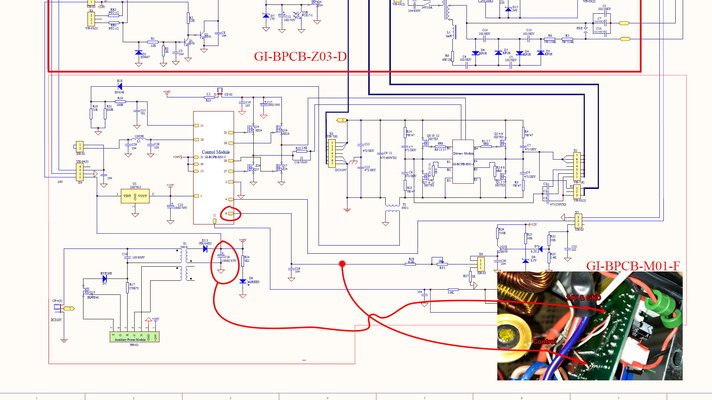

43 plasma cutter circuit diagram

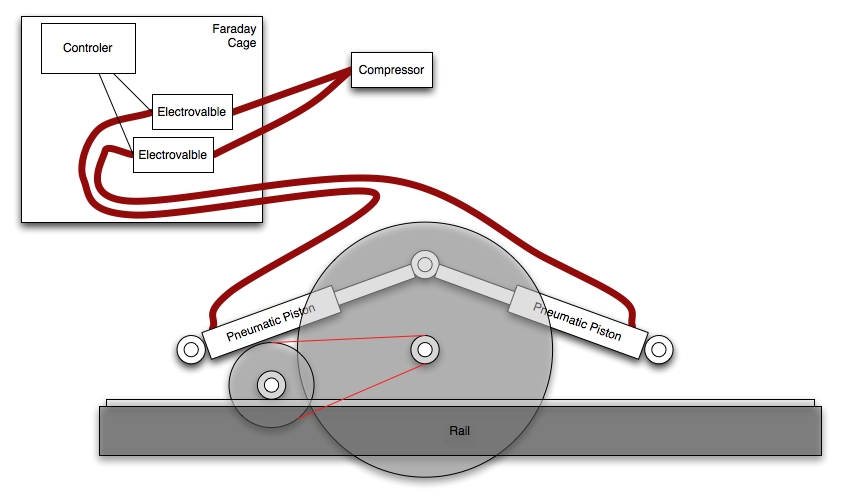

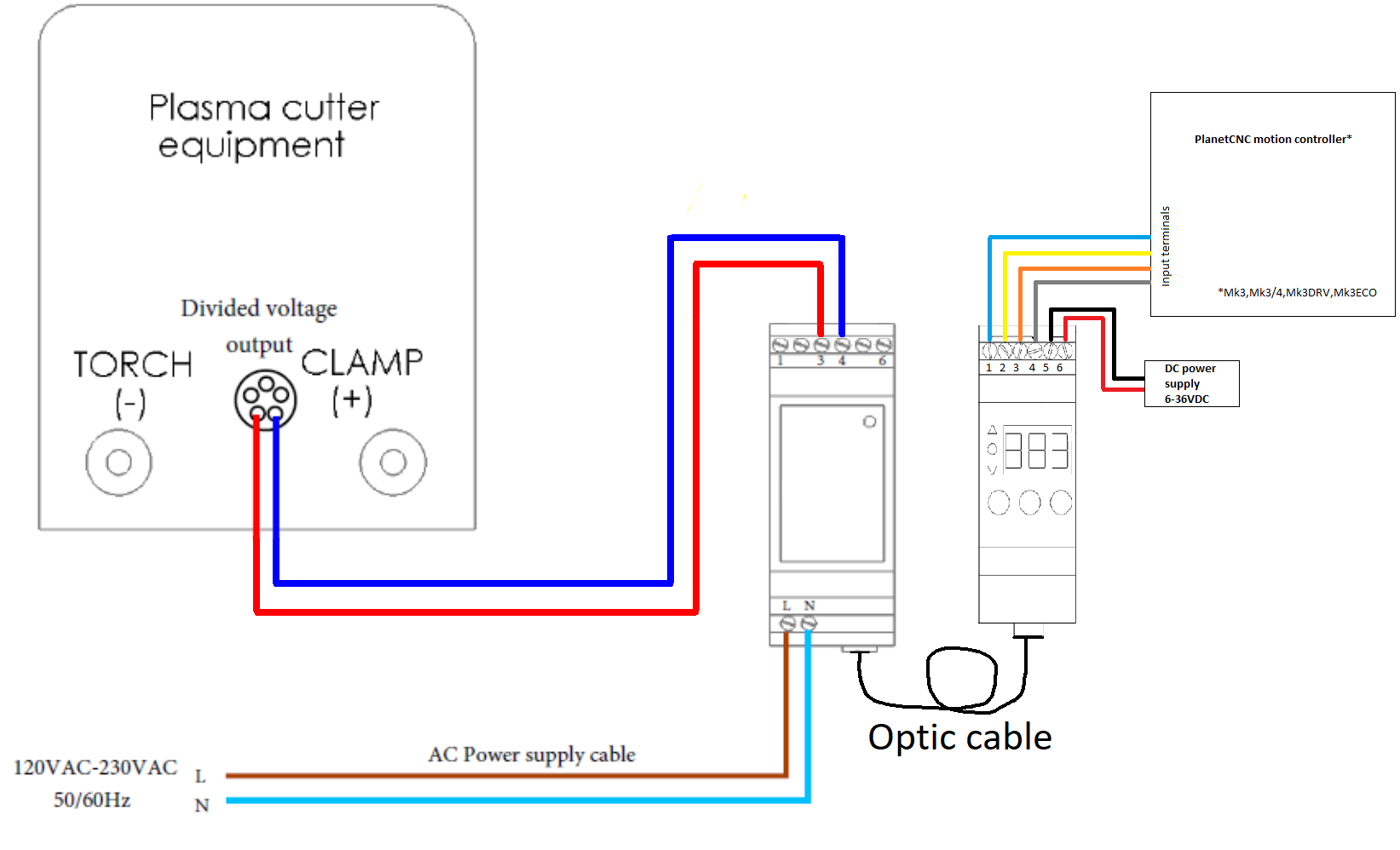

› news › research-newsPassive radiative cooling improves high-end solar cells Feb 10, 2022 · Under ~900W/m 2 direct sunlight, radiative gratings caused a 6°C temperature drop, 2% increase in open-circuit voltage, and 0.5 mA increase in short circuit current compared with plain glass, said the university. “Before our study, research has largely focused on single-junction solar cells and computational evaluations,” said Lee. › publication › 303370721_Study(PDF) Study on computer numerical control (CNC) machines [Show full abstract] switches, on/off relay to command the activation of the plasma torch, plasma cutter. The controller was connected to the personal computer through its parallel port.

openbuilds.comBuild List - OpenBuilds A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances.

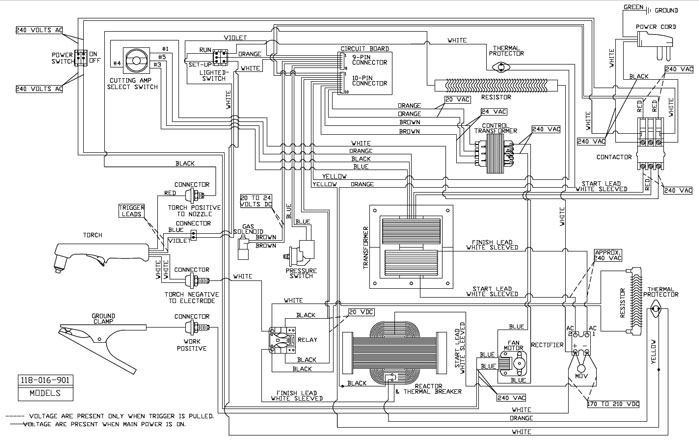

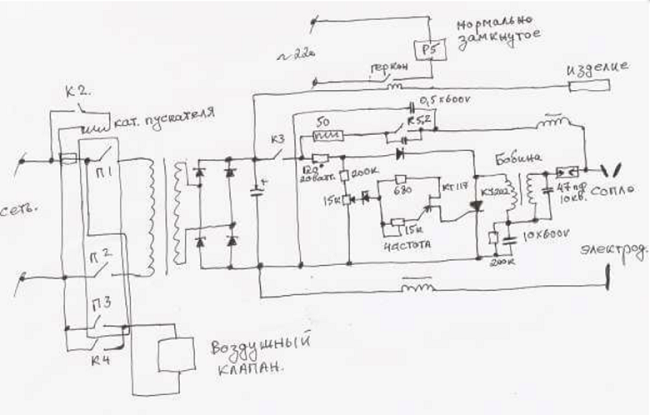

Plasma cutter circuit diagram

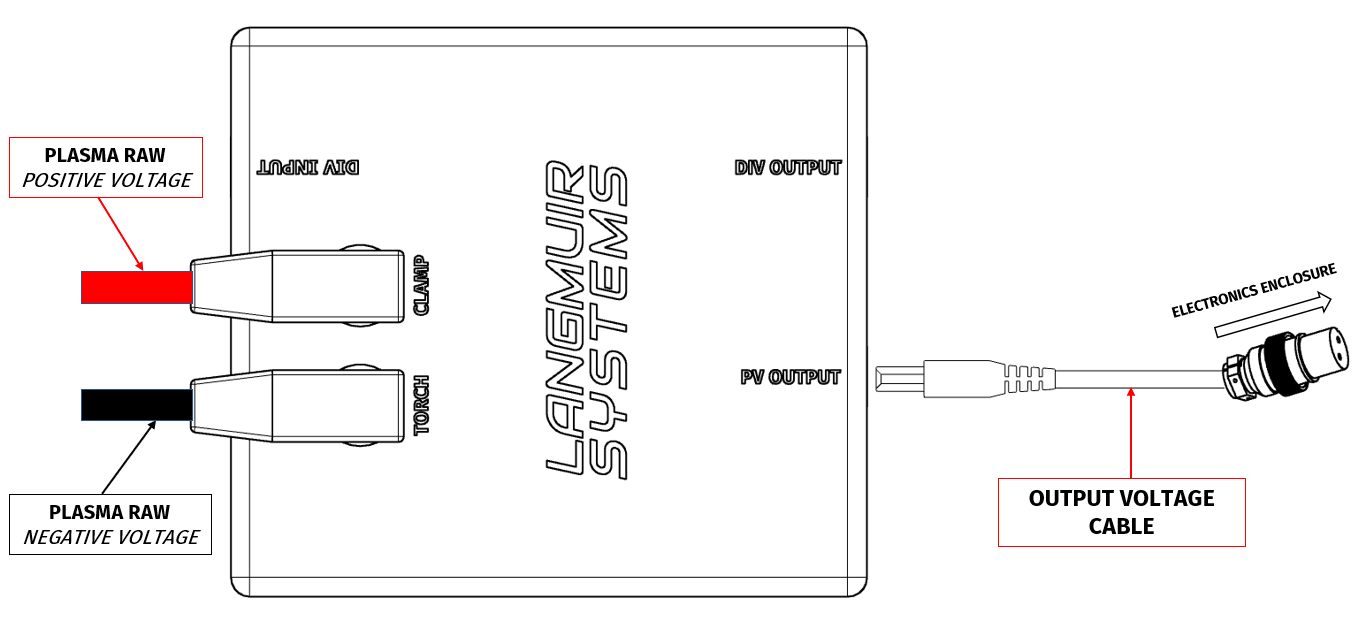

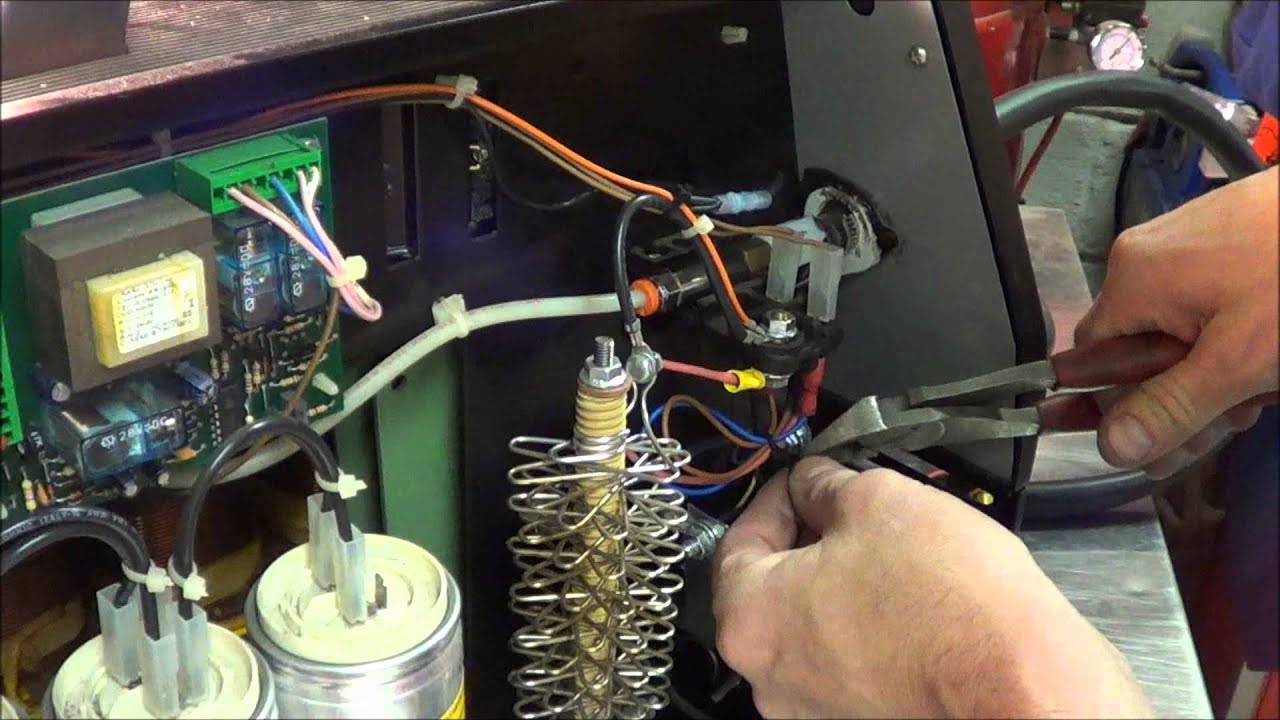

How to Make Your Own Plasma Cutter.... - Instructables 20 steps1.When I started assembling my cutter, I began with taking a good look at my parts. As shown in Section 5 and Section 6, my parts are laid out so I can begin ...2.Parts List3.Warning Warning 40 AMP AIR PLASMA CUTTER - White International Inspect Torch for any wearing, cracks or exposed wires. Replace or repair before use. • Check for proper fan operation. WEEKLY. Check your air and moisture ...16 pages › articles › custom-manufacturingUnderstanding Plasma Arc Cutting - Thomasnet Feb 23, 2022 · Figure 1 – Plasma Arc Electrical Polarities. Pilot Arc Initiation. The process begins with a start command prompting the power source to generate up to 400VDC of open-circuit voltage—i.e., no-load voltage—and initiating the flow of compressed plasma gas into the plasma torch assembly, which contains an electrode and a plasma nozzle.

Plasma cutter circuit diagram. › articles › custom-manufacturingUnderstanding Plasma Arc Cutting - Thomasnet Feb 23, 2022 · Figure 1 – Plasma Arc Electrical Polarities. Pilot Arc Initiation. The process begins with a start command prompting the power source to generate up to 400VDC of open-circuit voltage—i.e., no-load voltage—and initiating the flow of compressed plasma gas into the plasma torch assembly, which contains an electrode and a plasma nozzle. 40 AMP AIR PLASMA CUTTER - White International Inspect Torch for any wearing, cracks or exposed wires. Replace or repair before use. • Check for proper fan operation. WEEKLY. Check your air and moisture ...16 pages How to Make Your Own Plasma Cutter.... - Instructables 20 steps1.When I started assembling my cutter, I began with taking a good look at my parts. As shown in Section 5 and Section 6, my parts are laid out so I can begin ...2.Parts List3.Warning Warning

Comments

Post a Comment